The Benefits of UV Direct Printing for ADA Signs

Posted by Kelly Brewster on

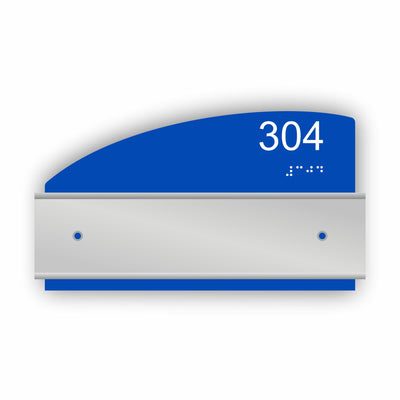

Here at Nap’s we use a direct to substrate UV Printer for all our customer ADA signage orders. Our UV Printing process enables us to provide our customers with a large variety of options and a high-quality products, along with being environmentally friendly.

What is UV Printing?

UV Printing refers to a commercial printing process that uses ultraviolet curing technology, with a different type of ink than conventional printing methods. This unique method of printing utilizing ultraviolet (UV) light to dry or cure, the ink. As the printer distributes ink on the surface of the material the UV lights follow close behind, “curing” or “drying” the ink instantly.

Our UV printer method used for producing our ADA signs offers our customer advantages because it can print to many materials that wouldn’t work with traditional inks, such as Aluminum, Plastic, Foam Board, Acrylic, Coroplast and more. We strive to make sure our customers receive the highest quality products.

Nap's uses this UV printing technology to produce our Compliant Tactile ADA Signs. The raised UV printing is a spot UV technique that builds up the UV coating to create dimension you can both see and feel, great for ADA Tactile Lettering and Braille.

Here are some more advantages to our UV Print Process …

QUICK DRYING TIME

In UV printing, lights are used for curing instead of heat; drying it as soon as it is applied, so no fumes or ozone are released, making the technology environmentally friendly! Also, the quick drying time reduces the interaction of the chemicals on the substrate, which means you can print to a wider variety of substrates unlike other conventional printing methods.

The quick dry time also lends to faster second surface printing for signage, lending to more options for our customers! No time is lost waiting for the ink to dry before folding, bending, packaging or performing other finishing details. This drying time also allows Nap's to make sure we offer our customers a fast turn around time!

SHARPNESS OF COLOR AND FINE DETAILS

UV printing is sharper, details finer and color are more vibrant due to the quick drying time. There is very little chance of the ink dots spreading, bleeding across the substrate because it is drying at a fast pace.

SCRATCH RESISTANCE

The inks also have improved physical properties, improved gloss finish, better scratch and hardness resistance, better elasticity and the finish product also benefits from improved strength. With the better scratch resistance, the printed signs are easier to handle, transport, package and install than traditionally printed signs. All this lends to added durability and the longevity of the graphics and signage.

FASTER PRODUCTION

The UV instant curing process that occurs with the direct to substrate printer means production will be faster than other methods. Not only does the method speed up production, meaning more is done in less time, rejection rates are reduced as the quality is higher.

COST EFFECTIVE

UV printing is most cost effective because you do not need to purchase any additional materials for the final printed sign. There is no need to protect the face of the sign by adding a top lamination.

ENVIRONMENTALLY FRIENDLY – Green Technology

The UV printing process is kinder to the environment too. Because the ink dries almost immediately and is not solvent-based, there is no chance for it to evaporate and so there are no Volatile Organic Compounds, toxic fumes or ozone released, making the technology environmentally friendly with almost a zero-carbon footprint! The lack of VOCs emitted means the practice is more sustainable.

Nap's love to offer a green technology within our printing department. We strive to make sure each ADA sign order is complaint, quality materials, and has a fast turn around time!

Shop at www.napADAsigns.com or call us at 800-451-3330

Share this post

- Tags: ADA, Braille, Designer ADA Signs, Exit EDA Signs, interior signs, sign, Standard ADA Signs, tactile signs, UV Printing